Brass welding filler rod is a type of filler material used to join two pieces of brass together. It is typically made of a copper-tin alloy, with the amount of tin varying depending on the desired properties of the weld. For example, a higher tin content will give a stronger weld but will also be more brittle.

Brass welding filler rod can be used with a variety of welding processes, including TIG, and stick welding. The specific process used will depend on the thickness of the brass being welded and the desired properties of the weld.

To weld brass with a filler rod, the following steps are typically followed:

- The brass surfaces to be welded must be clean and free of dirt, grease, and oxide.

- The filler rod must be the same composition as the brass being welded.

- The welding machine must be set to the correct settings for the type of welding process being used.

- The filler rod is melted into the joint between the two pieces of brass.

- The weld is allowed to cool and solidify.

Brass welding filler rod can be a versatile and effective way to join two pieces of brass together. However, it is important to use the correct type of filler rod and welding process for the specific application.

Here are some additional tips for welding brass with a filler rod:

- Use a low heat setting to avoid overheating the brass.

- Use a shielding gas to prevent the weld from oxidizing.

- Apply the filler rod in a smooth, even motion.

- Inspect the weld after it has cooled to make sure it is complete and free of defects.

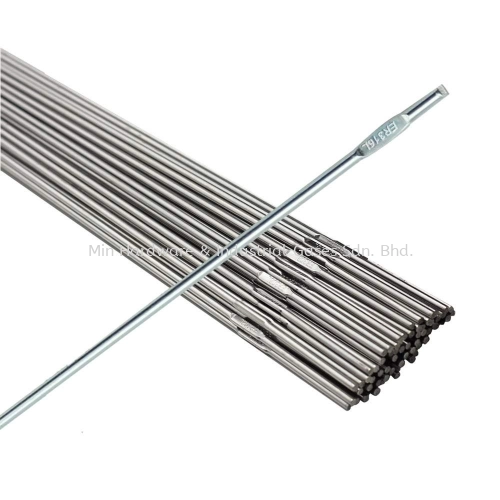

Inquiry - TIG Filler Rod Brass Rod